Cooperate With Powerful Manufacturer

Advantages:

1. Factory direct

2. Many exclusive explosive products

3. Professional technical traning team

4. Fully support exclusive agents

5. Outstanding design

6. OEM/ODM customization

Requirements:

1. Powerful distributors in your country

2. Owners of high-quality mobile phone stores in your country

3. Influencer in the local vertical

ABOUT US

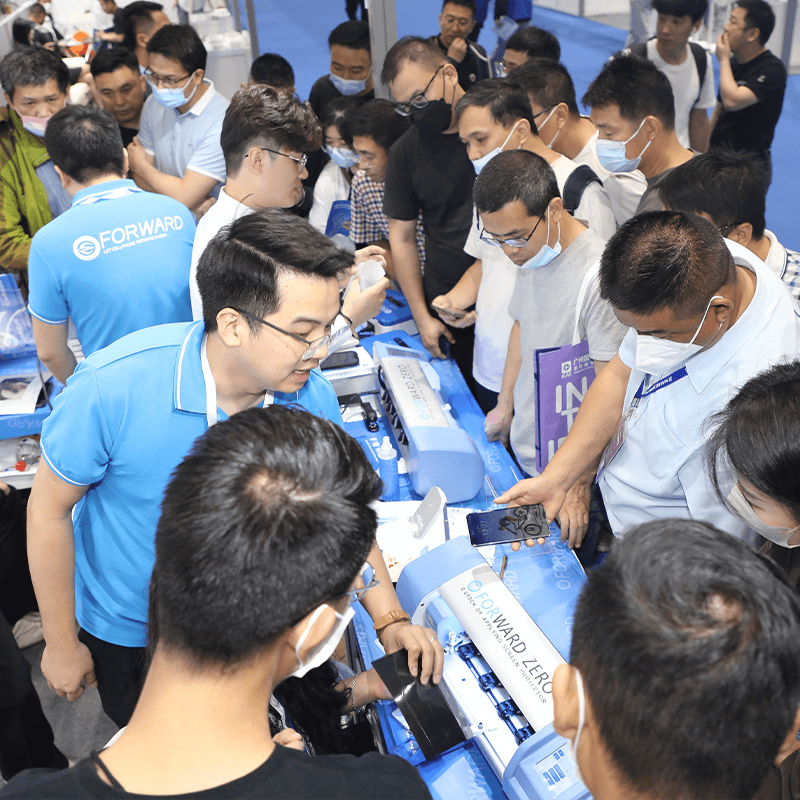

Why Choose Forward?

FORWARD

Numbers we are proud of

- Our brand is recognized all over the world, and these figures witness

our development in the international market, would you like to be our

business partner?

- You can choose to become our exclusive distributor and after signing

the agreement, you will be the sole importer in the local market and

our high quality products will only be sold to you.

Happy clients

0

+

Years old

0

+

From Countries/Regions

0

+

Successful

0

+

Employees

0

+

Factory size

0

+

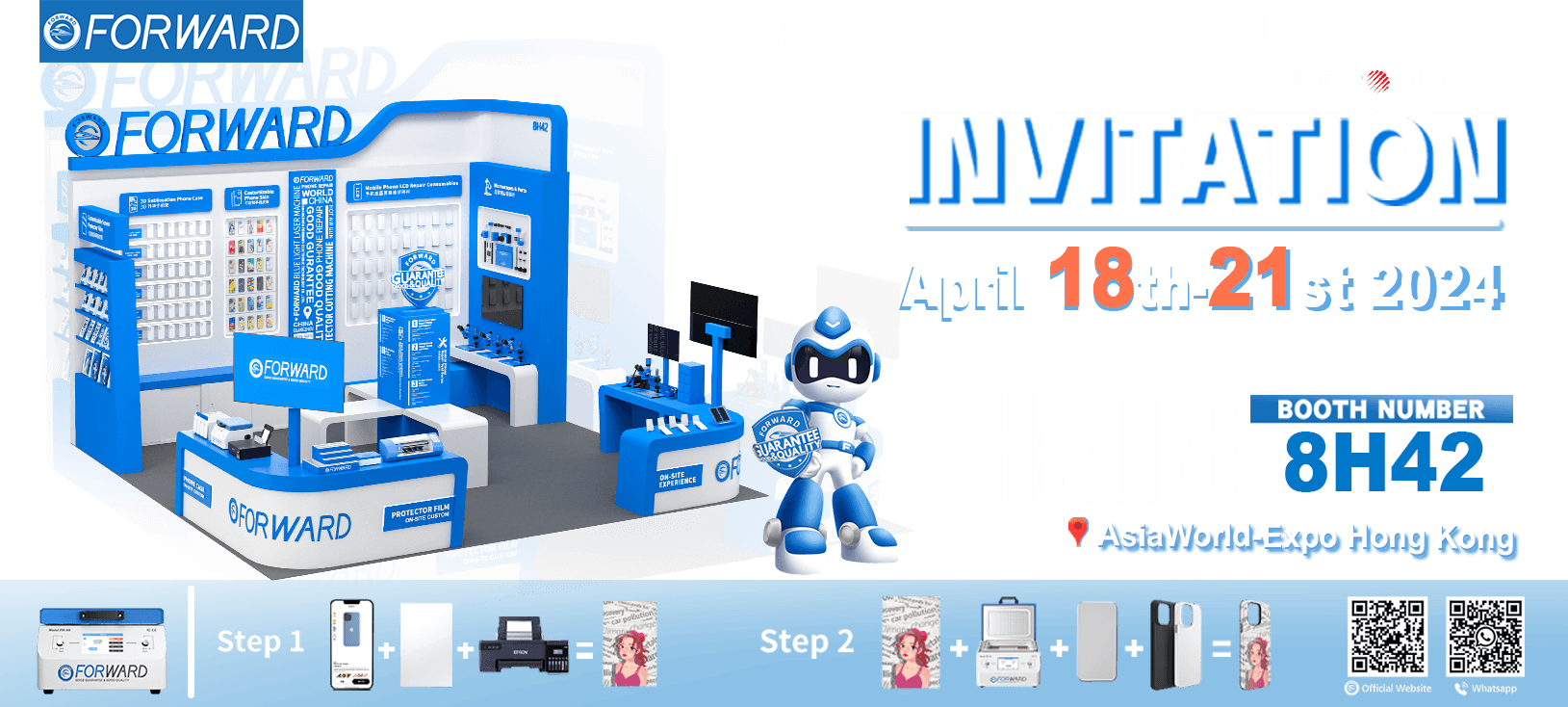

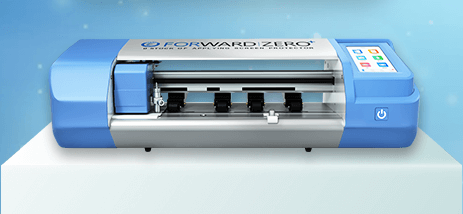

SOLUTION

One-Stop Solution

EVALUATE

Big Influencer Favorite

BLOGS

Recent Posts

VIDEO

Recent Videos

Start Earning Substantial Profits In Your Country Toady!

Phone repair machine&tools and phone accessories wholesale can be easy. FORWARD has helped customers in more than 30 countries to be suc-cessful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first,and we will execute your custom product' design after you send us the first time. Click the buttons below, and let's grow your business together.